Debris Chute System

Key Features

- Single point collection of entire building construction and demolition (C&D) waste.

- Easy to use, assemble and dismantle as per requirement.

- Reusable for multiple sites or projects.

1. Mild Steel Chute with colour coating

- Male / Female and C clamp type

2. Plastic Drum Chute

- Mile steel structure and C clamp type.

- Spray painting with hardner.

- Mounting: Floor support structure, anchor fastener.

Features

When discussing the features of a linen chute system, it encompasses not just the chute itself but also the entire system of components and infrastructure supporting its operation. Here are the key features:

1. Chute Structure:

The chute itself is a crucial component. It should be constructed from durable and fire-resistant materials such as stainless steel or fire-rated plastic to ensure longevity and safety.

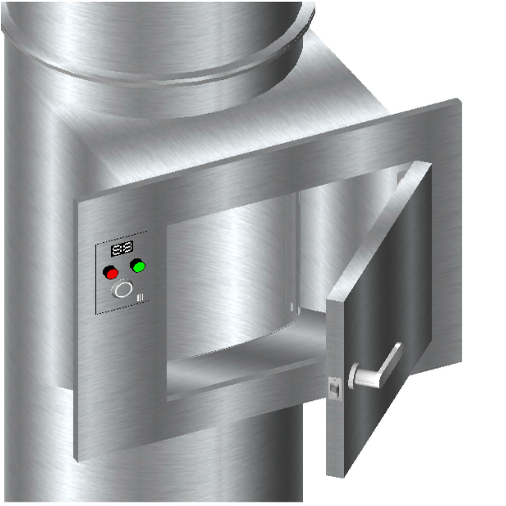

2. Chute Doors:

Entry doors on each floor allow users to deposit laundry or linens into the chute.

These doors should be self-closing and equipped with safety locks to prevent unauthorized access and ensure compliance with fire safety regulations.

3. Discharge Area:

- At the bottom of the chute, there should be a designated collection point where the laundry or linens accumulate for removal.

- This area should be easily accessible for maintenance and cleaning.

4. Ventilation System:

- Proper ventilation is essential to prevent odors and maintain airflow within the chute system.

- Ventilation components such as fans, vents, and exhaust systems help ensure air circulation and prevent the buildup of moisture and odors.

5. Fire Safety Measures:

- Linen chute systems must adhere to fire safety regulations, including the installation of fire-rated doors, fire suppression systems, and fire alarms.

- These measures help contain and prevent the spread of fire through the chute system.

6. Interlock System:

- An interlock system prevents multiple chute doors from being open simultaneously, reducing the risk of accidents and ensuring user safety.

7. Cleaning Access Points:

Access panels or doors at various points along the chute system allow for easy cleaning, inspection, and maintenance.

These access points are essential for ensuring the cleanliness and proper functioning of the chute system.

8. Monitoring and Control Systems:

- Advanced chute systems may include monitoring and control systems to track usage, detect blockages or malfunctions, and provide alerts or notifications for maintenance and repairs.

9. Noise Reduction Features:

- To minimize noise and disturbance, some chute systems incorporate sound-absorbing materials, baffles, or other noise-reduction features within the chute structure.

10. Labeling and Signage:

- Clear labeling and signage throughout the chute system provide instructions for proper use, safety guidelines, and emergency procedures.

Usage of Debris Chute System

Mild Steel Chute with color coating

Plastic Drum Chute

Debris Chute System for Building

Call To Action

Get In Touch

Call To Action

Get In Touch

Plans

Price & Plans

Property

$199

One Time Instalation

- 2 Bedrooms cleaning

- Vacuuming

- 2 Bathroom cleaning

- Window cleaning

- Floor cleaning

Office

$299

One Time Instalation

- 2 Bedrooms cleaning

- Vacuuming

- 2 Bathroom cleaning

- Window cleaning

- Floor cleaning

Property

$399

One Time Instalation

- 2 Bedrooms cleaning

- Vacuuming

- 2 Bathroom cleaning

- Window cleaning

- Floor cleaning

How It Work?

The Debris Chute System functions on a straightforward yet highly efficient mechanism designed for the safe and convenient disposal of construction debris.

1. Entry Point Access:

Workers access the designated entry points located at various levels of the construction site.

These entry points are typically positioned near areas where demolition or construction work is ongoing to ensure easy access for workers.

2. Deposition of Debris:

- Construction debris, such as rubble, broken materials, or waste, is deposited into the chute entry points by workers.

- The chute entry points are designed with wide openings to accommodate large debris items, ensuring swift and hassle-free disposal.

3. Gravity-Driven Conveyance:

- Once deposited into the chute, gravity takes over, propelling the debris downward through the chute’s inclined channels.

- The chutes are designed with a gentle slope to facilitate the smooth flow of debris, minimizing the risk of blockages or slowdowns.

4. Segregation (Optional):

Depending on the specific requirements of the construction project, the Debris Chute System may feature multiple chutes for segregating different types of debris. For instance, separate chutes may be designated for wood, concrete, metal, or general waste, allowing for efficient recycling or disposal as per project needs.

5. Centralized Collection:

At the base of the chute system, a centralized collection area accumulates the debris as it exits the chutes.

This collection area is often located near ground level for easy access by cleanup crews or waste management personnel.

6. Removal and Disposal:

- Once the debris accumulates at the collection point, it is promptly removed and disposed of according to waste management protocols and environmental regulations.

- Cleanup crews or waste management services may utilize trucks or containers to transport the debris to appropriate disposal facilities.

7. Maintenance and Safety:

- Regular maintenance of the Debris Chute System is crucial to ensure its continued functionality and safety.

- Inspections are conducted to check for any signs of wear, damage, or blockages in the chutes, while cleaning and disinfection routines help prevent odors and maintain hygiene standards.

Contract System

Maintenance Contract

1. We would like to inform you that, we are providing The Annual Maintenance / Service Contract of our or any other make Garbage Chute / Linen chute. 2. Maintenance contract consist of regular examinations and any rginor necessary adjustments of the equipment by competent employees under direction and supervision.

Benefit of Debris Chute

Creating a benefit of a debris chute system involves highlighting its advantages in various aspects such as safety, efficiency, cost-effectiveness, and environmental impact. Here’s how you can emphasize the benefits:

1. Safety:

- Reduce the risk of accidents and injuries associated with manual handling and transportation of debris down from elevated areas.

- Minimize the chances of falling debris that could harm workers or pedestrians below.

- Ensure compliance with safety regulations and standards by providing a safe method for debris disposal.

2. Efficiency:

- Streamline the debris removal process, allowing for quicker and more efficient cleanup of construction sites or renovation projects.

- Increase productivity by saving time and labor that would otherwise be spent manually carrying debris down stairs or elevators.

- Enable simultaneous removal of debris from multiple floors, enhancing workflow and project timelines.

3. Cost-efffectiveness :

- Reduce labor costs associated with manual debris removal.

- Minimize potential damage to property or structures caused by dropping or dragging debris during manual removal.

- Enhance overall project cost-effectiveness by optimizing resource utilization and project timelines.

4. Environmental Impact:

- Reduce the risk of environmental pollution by containing and controlling debris during removal.

- Minimize the need for excessive cleanup efforts post-construction, leading to less waste generation.

- Improve sustainability by promoting efficient waste management practices, potentially facilitating recycling or proper disposal of debris.

5. Versatility and Adaptability:

- Suitable for various construction and renovation projects, including high-rise buildings, commercial properties, and residential complexes.

- Can be easily installed and adjusted to fit different site requirements and configurations.

- Compatible with different types of debris, including concrete, wood, metal, and general construction waste.

6. Enhanced Site Organization:

- Maintain a cleaner and more organized work environment by containing debris within designated chutes.

- Reduce clutter and obstruction on-site, improving overall safety and accessibility for workers and equipment.

7. Customer Satisfaction:

- Enhance client satisfaction by demonstrating a commitment to safety, efficiency, and responsible waste management practices.

- Minimize disruptions to surrounding areas or neighboring properties during construction or renovation activities.